How piezoresistant sensors work in metal components and structures

Critical components are key to systems running effectively. However, established methods for these components, such as ILI monitoring or visual inspection, often are performed only periodically, and if serious damage occurs to those components between inspections, these methods can be ineffective. Critical components, such as pipelines, pressure vessels, gaskets, or connectors are in need of a more comprehensive, continuous monitoring technology- especially for larger monitoring areas.

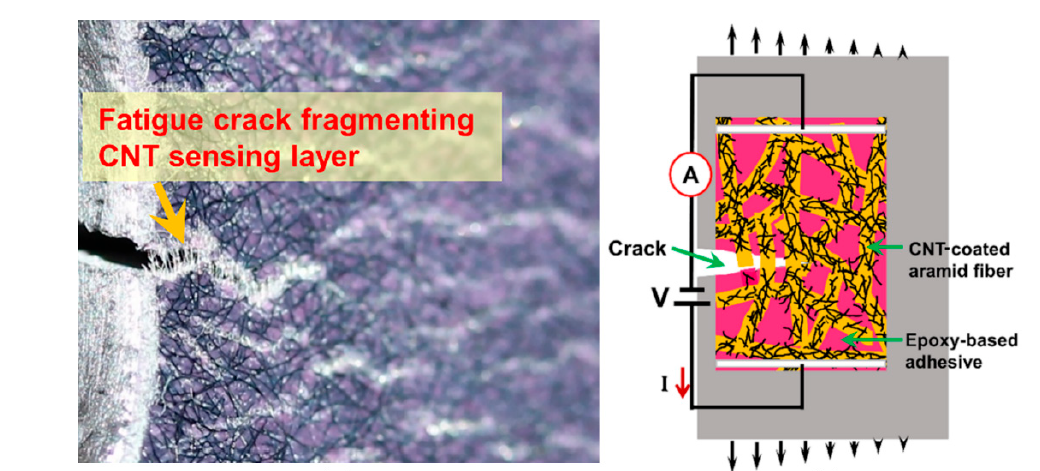

In research related to the use of carbon nanotube-based sensing skins with metals, we have demonstrated the successful use as strain sensors when bonded to both aluminum and steel. The sensor used in this work combines the concept of networks of CNTs as piezoresistive sensors with the use of a nonwoven carrier fabric carrier to easily deploy the sensor in applications that cover large areas and complex geometries. The fabric acts as a carrier for the electrically conductive sensing network, which has been utilized as a sensor in the bondline of metal–composite hybrid structures through previous research.

The piezoresistive response of the carbon nanotube network is due to the nanotube -nanotube "tunneling resistance" within the film. The electrically percolating network of nanotubes on the surface of the material changes due to compression, and the compressive stress in the film at the fiber crossover results in a local decrease in the film electrical conductivity. As a result, the resistance decreases with continuously applied pressure. These principles can be applied to many different potential issues that affect critical components, such as bolt relaxation, over-tightening, dents, structural cracks, or structural strain.

Diagram used from published article in publication Sensors. "Performance Evaluation of a Carbon Nanotube Sensor

for Fatigue Crack Monitoring of Metal Structures." Shafique Ahmed 1, Thomas Schumacher, Erik T. Thostenson and Jennifer McConnell.

%20Final%20(2).png?width=670&height=375&name=M-CET%20_Logo(s)%20Final%20(2).png)