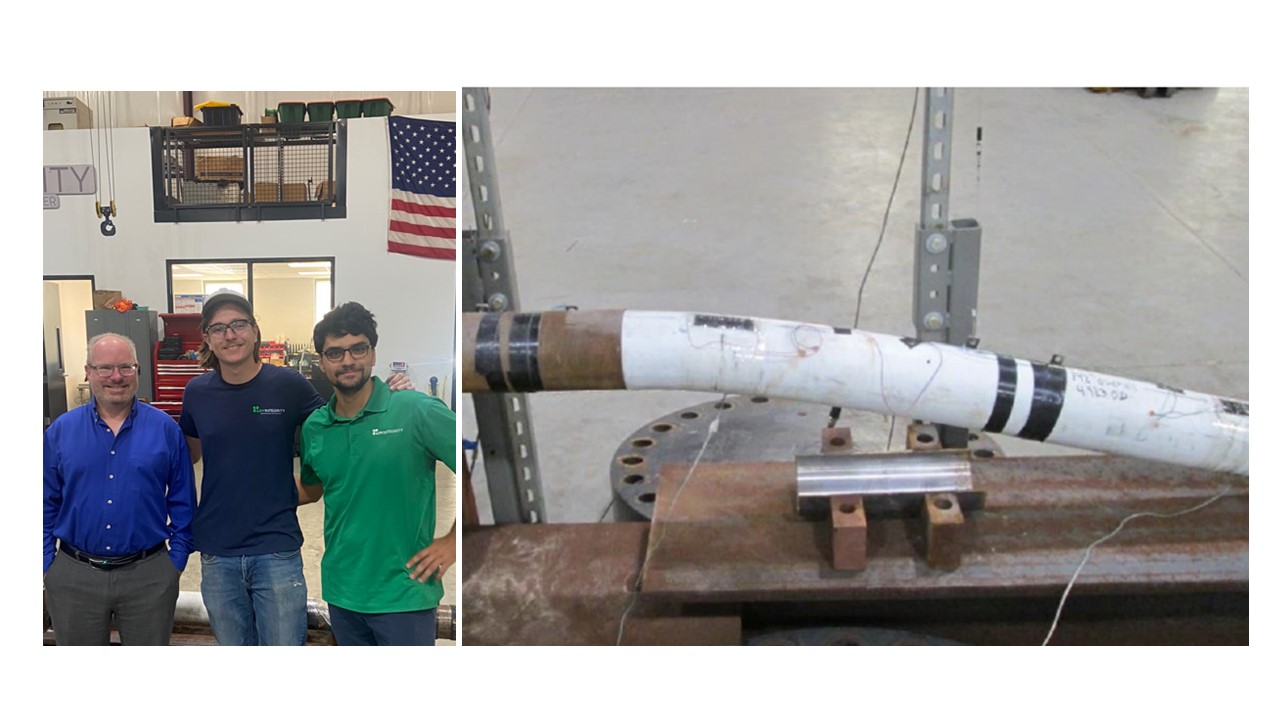

MCET Completes Independent Pipe Stress/Strain Test

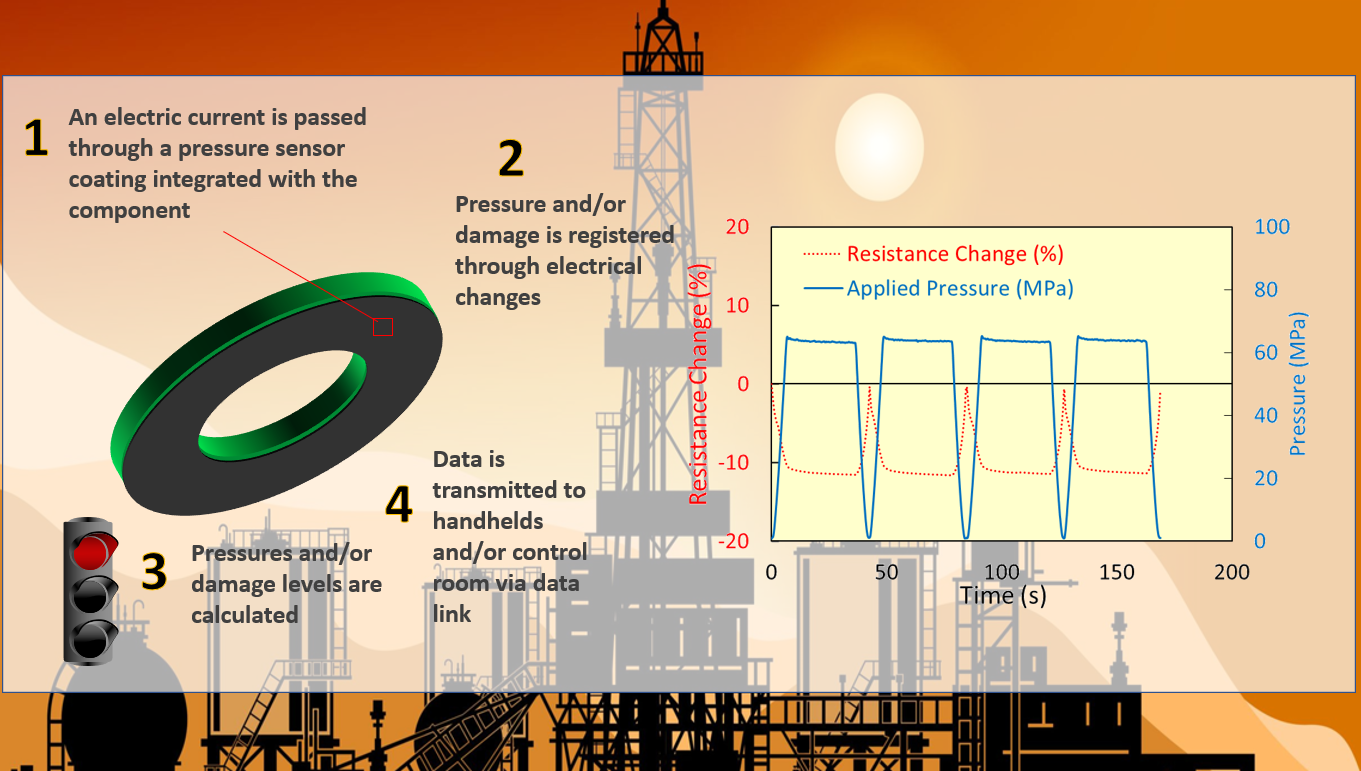

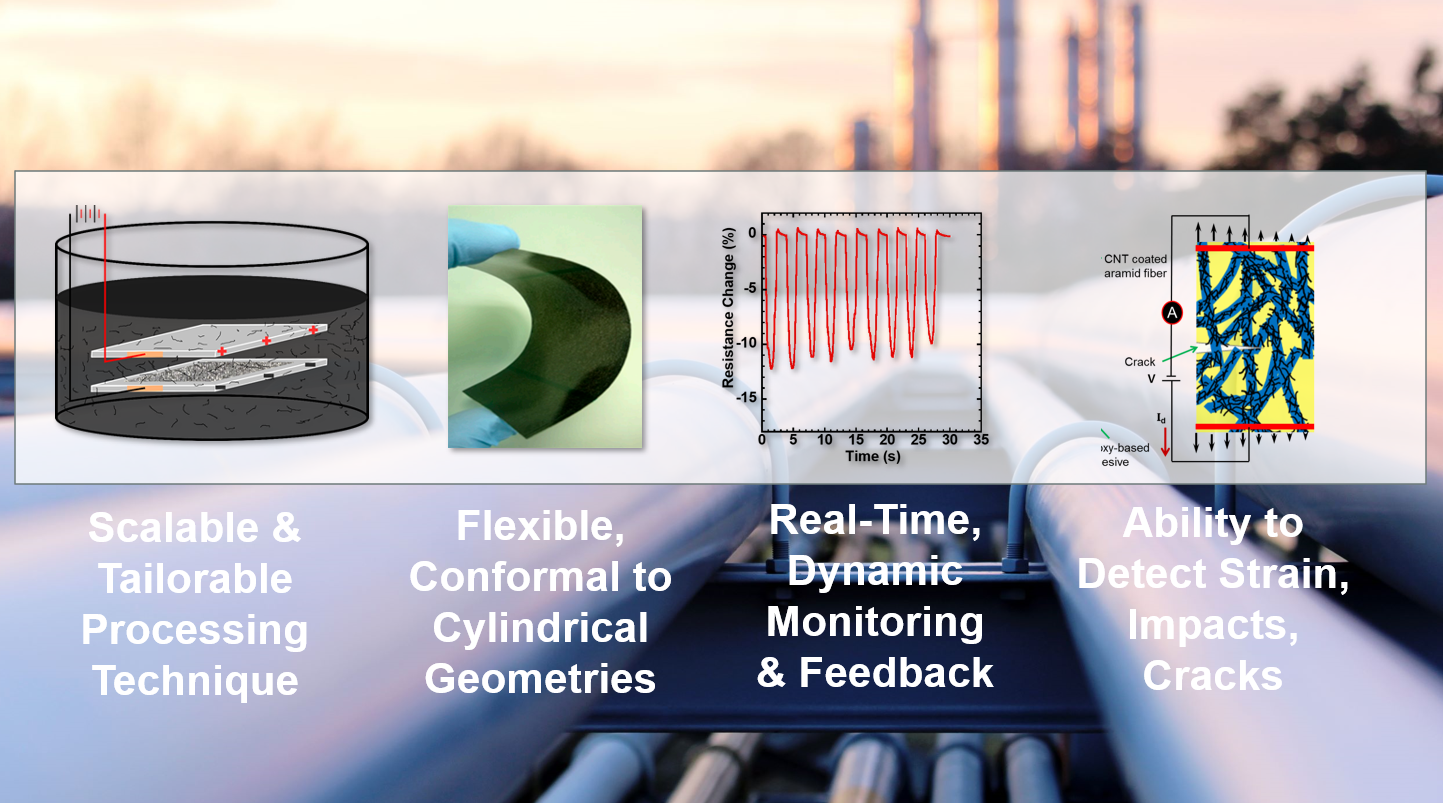

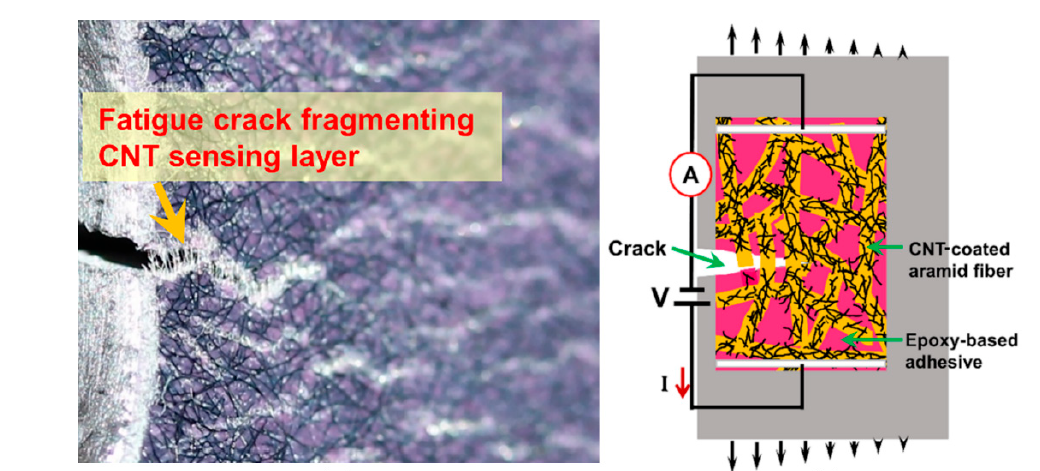

MCET recently participated in the second Combined Loading Assessment of Spoolable Pipe Systems (CLASPS-02) Joint Industry Program (JIP), a program designed to evaluate current non-destructive examination (NDE) technologies and assessment of defects caused common threats to pipelines.

%20Final%20(2).png?width=300&height=168&name=M-CET%20_Logo(s)%20Final%20(2).png)

-3.jpg)

.jpg)