Piezoresistive Advantages in Structural Monitoring

Globally, industrial facilities in Power Utility, Petrochemical and other industrial capacities commonly use pressure vessel and piping equipment (PVP) in a number of applications, including utility boilers, petrochemical storage and transport, or manufacturing processes. However, while the use of PVP in these applications is considered to be highly reliable, accidents can happen, and they can cause serious injury or death to workers as well as important infrastructure and equipment damage. Even a small leak of a confined fluid can lead to serious consequences in terms of human health and safety, environment damage, and productivity loss. Continuous NDT structural monitoring solutions are needed to address these concerns.

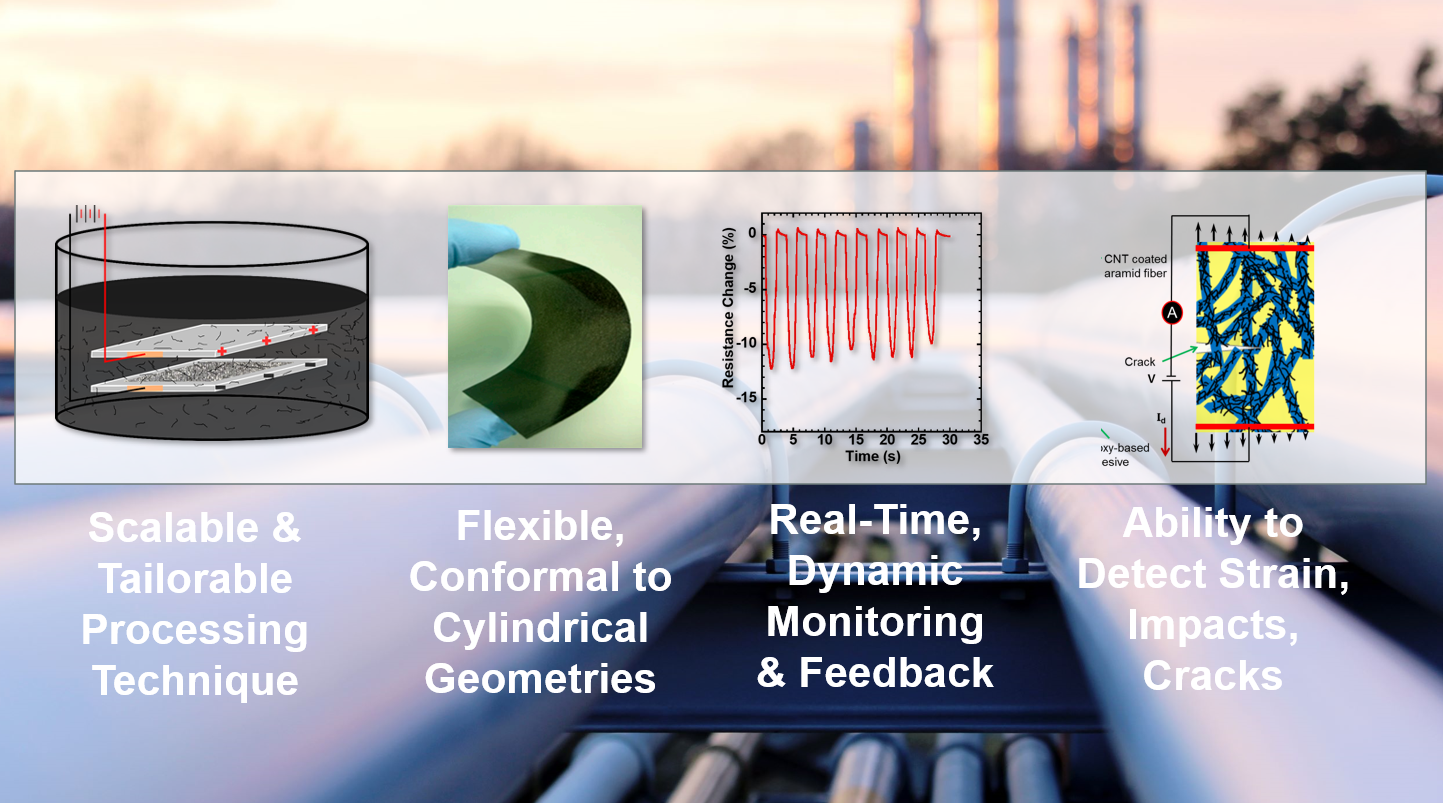

MCET piezoresistive sensors are sensitive to the extremely wide pressures ranges that characterize industrial applications. The sensors have been shown to have the potential to measure from the tactile range (<10 kPa) to very high pressures (∼60 MPa). Our patented EPD technique enables the creation of a uniform carbon nanotube-based nanocomposite coating, in the range of 250−750 nm thick. The electrically conductive nanocomposite coating is firmly bonded to the material surface, and the pressure sensor displays a large in-plane change in electrical conductivity with applied out-of-plane pressure. As a result, our CNT technology can be applied in many different types of industrial applications, including high pressure PVs and composite designs.

%20Final%20(2).png?width=670&height=375&name=M-CET%20_Logo(s)%20Final%20(2).png)