MCET Technologies News & Research

MCET Technologies News & Research

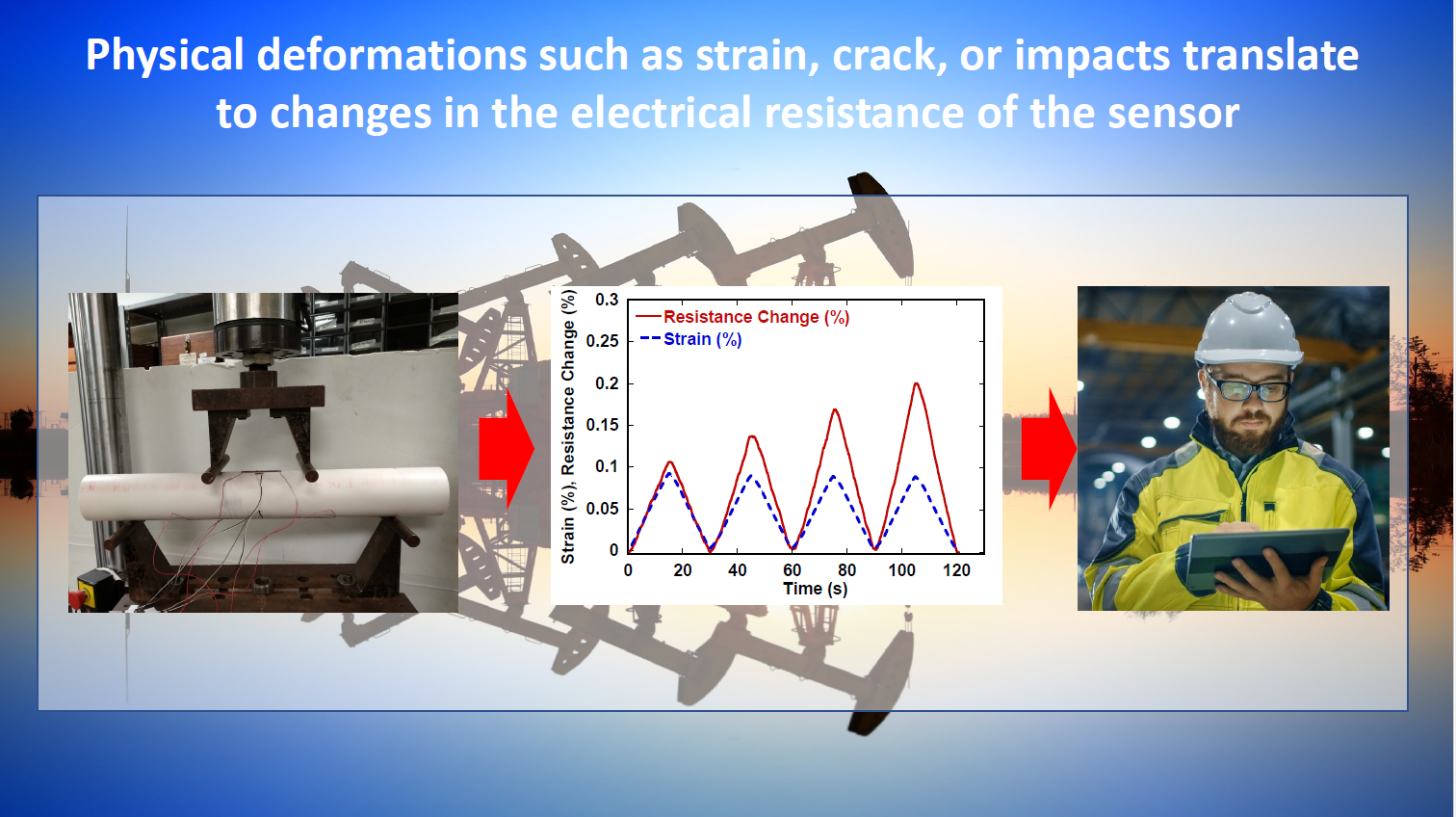

How piezoresistant sensors detect and monitor damage

.jpg?height=70&name=Erik%20(2).jpg)

Dr. Erik T Thostenson

Globally, at least 6.2 million miles of pipeline transport gas, oil, and chemicals to 700 refineries, 24,500 power utility plants, and tens of thousands of industrial facilities globally, of which 60% of those pipelines are in the US. Pipeline infrastructure failures represent significant hazards in terms of personal injury (2,000-4,000 injuries/yr in the US O&G industry), environmental damage, and monetary losses due to fines, cleanups, and system shutdowns that can approach $1M/day.

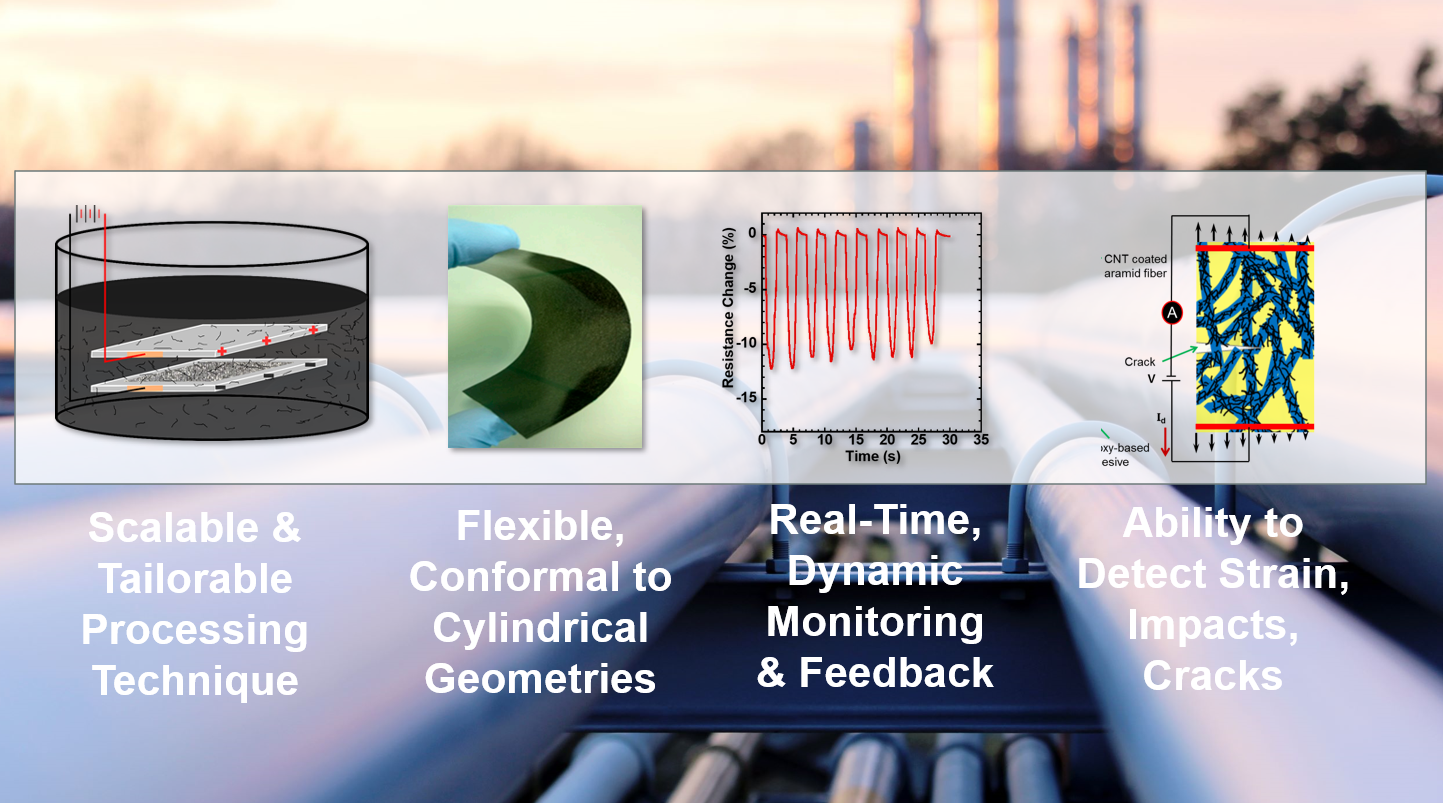

Piezoresistive Advantages in Structural Monitoring

Dan Bryan

Globally, industrial facilities in Power Utility, Petrochemical and other industrial capacities commonly use pressure vessel and piping equipment (PVP) in a number of applications, including utility boilers, petrochemical storage and transport, or manufacturing processes. However, while the use of PVP in these applications is considered to be highly reliable, accidents can happen, and they can cause serious injury or death to workers as well as important infrastructure and equipment damage. Even a small leak of a confined fluid can lead to serious consequences in terms of human health and safety, environment damage, and productivity loss. Continuous NDT structural monitoring solutions are needed to address these concerns.

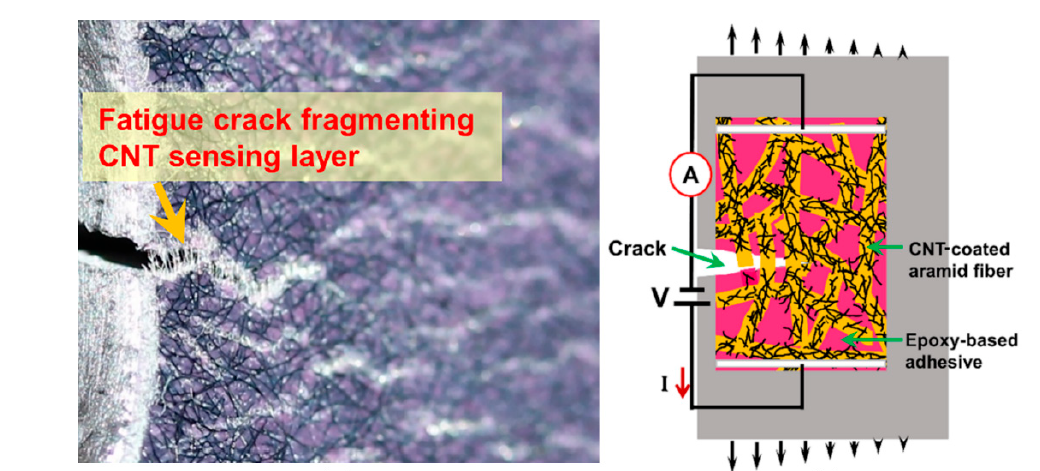

How piezoresistant sensors work in metal components and structures

Dan Bryan

Critical components are key to systems running effectively. However, established methods for these components, such as ILI monitoring or visual inspection, often are performed only periodically, and if serious damage occurs to those components between inspections, these methods can be ineffective. Critical components, such as pipelines, pressure vessels, gaskets, or connectors are in need of a more comprehensive, continuous monitoring technology- especially for larger monitoring areas.

.jpg)

Pipeline damage detectable through continuous piezoresistive sensors

.jpg?height=70&name=Sagar%20(2).jpg)

Dr. Sagar M Doshi

The average yearly costs of US pipeline incidents increased to approximately $733M/yr from the period of 2016-20, an increase over the previous five years. These hazards represent significant costs in terms of personal injury (2,000-4,000 injuries/yr in the US Oil & Gas industry), environmental damage, and monetary losses due to fines, cleanups, and system shutdowns that can approach $1M/day.

Use piezoresistive sensors to monitor tank strains and damage

Dan Bryan

There are tremendous financial costs and hazards associated with pressure vessel failures. These risks can include damage to infrastructure, environmental cleanup, and loss of human life. Given these high costs, there is a critical need for the development of tank structural health monitoring methods that can detect excessive physical strains and damage to the vessel in real time. The data must be collected in a live and continuous manner so that the owners of the pressure vessel can be immediately warned of structural health changes to the tank while in-service.

Is the tank damage serious... or not?

Dan Bryan

We all know that accepted PV or tank testing methods, including hydrostatic or acoustic testing procedures can find damage or corrosion. However, to check that damage, the tank has to be taken out of circulation in many cases- which may only happen once in as many as 15 years. You're left with visual inspection at some points when you can. Moreover, if it's a composite tank or PV- which are increasingly used due to strength and weight advantages- the damage may not even be noticeable in a visual inspection. Current methods for damage monitoring of composite structures can also be problematic- especially if water is involved.

MCET Technologies Selected for 2022 DOT Phase I Grant Award

Dan Bryan

MCET Technologies is one of 12 companies selected by the U.S. DOT’s highly competitive Small Business Innovation Research (SBIR) program awards contracts to domestic small businesses to pursue research on and develop innovative solutions to our nation’s transportation challenges.

Use piezoresistive technology to document patient recovery

Dan Bryan

When it comes right down to it, almost every one of the 1.5M Achilles Heel, ACL replacement, and ankle sprains every year require some sort of insurance involvement, which inevitably requires documentation- and that insurance documentation has to be specific. The clinic has to document things such as what patient is lacking, growth potential, and patient progress, which can be very difficult as the patient is only in the clinic for 1-2 hours a week. Moreover, if the clinic cannot fully document these points, there is a risk that they may not be paid by insurance. At times this can be a real challenge, as there may be a documentation gap between “what is specified by patient” and what is measured in the clinic.

%20Final%20(2).png?width=300&height=168&name=M-CET%20_Logo(s)%20Final%20(2).png)